Sugarcane, scientifically known as Saccharum officinarum, is a perennial tropical plant primarily known for its ability to produce sugar. This plant has a long history, dating back to ancient times in regions of Asia, before its introduction to the New World by European explorers.

Main Characteristics of Sugarcane

- Appearance: Sugarcane is a tall plant, reaching up to 6 meters in height. It has thick, fibrous stalks containing sugar.

- Cultivation: It is a plant that requires warm and humid climates for optimal growth. It is cultivated in tropical and subtropical regions worldwide.

- Reproduction: It reproduces primarily asexually, through the planting of stem pieces.

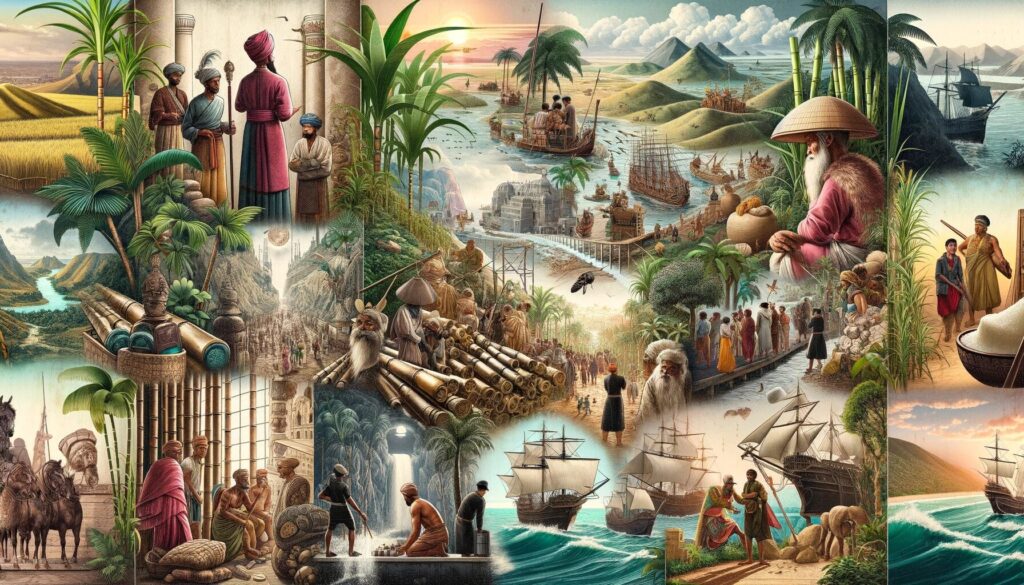

The History of Sugarcane

The history of sugarcane is fascinating and extensive, spanning thousands of years and multiple continents. Here’s a more detailed description:

Origins in Asia:

- Ancient Times: Sugarcane is native to Southeast Asia and the Indian subcontinent. Its cultivation is believed to have begun over 4,000 years ago.

- India: In India, sugarcane was cultivated for granulated sugar production from ancient times. Ancient Indian texts, such as the Atharvaveda (written around 2000 BCE), mention sugarcane, and by the 6th century BCE, sugar processing methods were quite advanced in this region.

- Spread to China: Sugarcane was introduced to China around the 7th century BCE. Chinese records from the time of Emperor Han Wu Di (156–87 BCE) mention sugarcane cultivation and granulated sugar production.

Expansion to the Middle East and Mediterranean:

- Silk Road: Through the famous Silk Road, sugarcane reached the Middle East, where sugar refining techniques were further perfected during the Islamic period.

- Crusades: During the Crusades (11th to 13th centuries), Europeans came into contact with sugarcane sugar. Its popularity grew in Europe, although initially, it was a luxury item.

Arrival in the New World:

- European Explorers: Christopher Columbus brought sugarcane to the New World on his second voyage in 1493. He planted it in the Caribbean islands, where the climate was ideal for cultivation.

- Plantation Era: Sugarcane cultivation rapidly expanded to the Caribbean islands, Brazil, and other parts of South and Central America. This led to the establishment of large plantations and was a key factor in the transatlantic slave trade, as intensive labor was needed to cultivate and process sugarcane.

Global Impact:

- Global Trade: Sugarcane was a key driver in the development of global trade between the 17th and 19th centuries, critically linking Europe, Africa, the New World, and Asia.

- Industrial Revolution: Sugarcane played a role in fueling the Industrial Revolution, not only as a commercial product but also as a source of calories for the growing urban population.

Sugar Production from Sugarcane

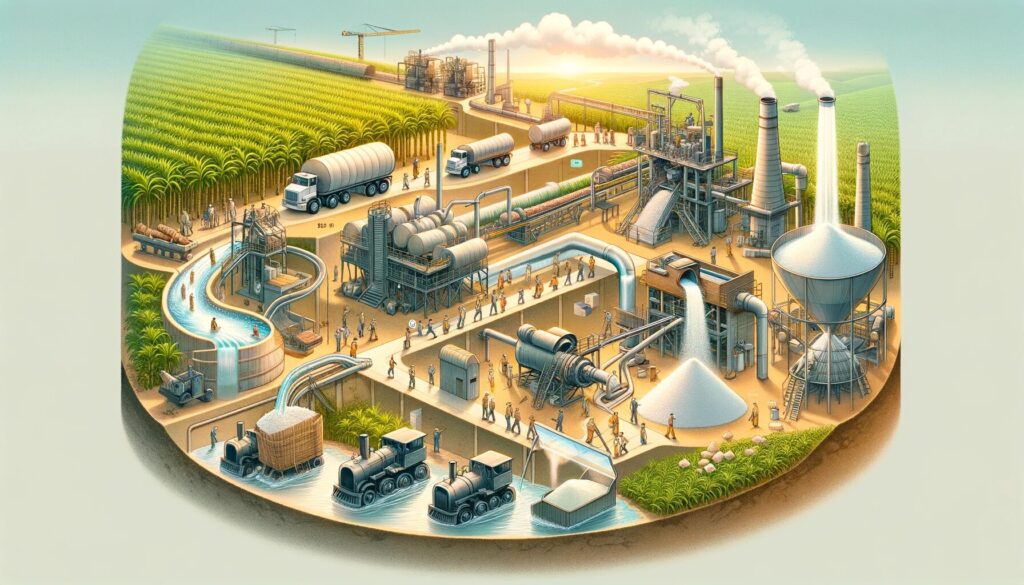

Sugar production from sugarcane is a complex process involving several steps. Here’s a breakdown of this process:

1. Sugarcane Harvesting:

- Manual or Mechanical Harvesting: Depending on the region and resources, sugarcane can be harvested manually or using machinery. Manual harvesting has been traditional in many countries, but mechanized harvesting has become more common to increase efficiency.

- Harvesting Timing: It’s important to harvest sugarcane at the right time, typically when the sucrose content is highest.

2. Transportation and Preparation:

- Transport to the Mill: After harvesting, sugarcane is quickly transported to sugar mills to avoid sugar loss.

- Cleaning and Crushing: Once at the mill, sugarcane is cleaned to remove leaves and other debris. It is then crushed to extract the juice. Crushing machines break the stalks’ cells to release the juice.

3. Juice Extraction:

- Milling: The crushed sugarcane passes through a series of mills that squeeze out the juice. This juice contains water, sucrose, and other compounds.

- Bagasse Separation: The bagasse, or fibrous residue left after juice extraction, is often used as biomass to generate energy at the same mill.

4. Juice Purification:

- Clarification: The raw juice is heated, and lime and other chemicals are added to precipitate impurities. These impurities are removed through sedimentation or filtration.

- Evaporation: The clarified juice is concentrated through evaporation in vacuum evaporators to increase its sucrose content.

5. Crystallization:

- Vacuum Cooking: The concentrated juice is further cooked under reduced pressure to promote sugar crystal formation.

- Centrifugation: The crystals are separated from the liquid (molasses) using centrifuges. The molasses can be further processed or used in other products.

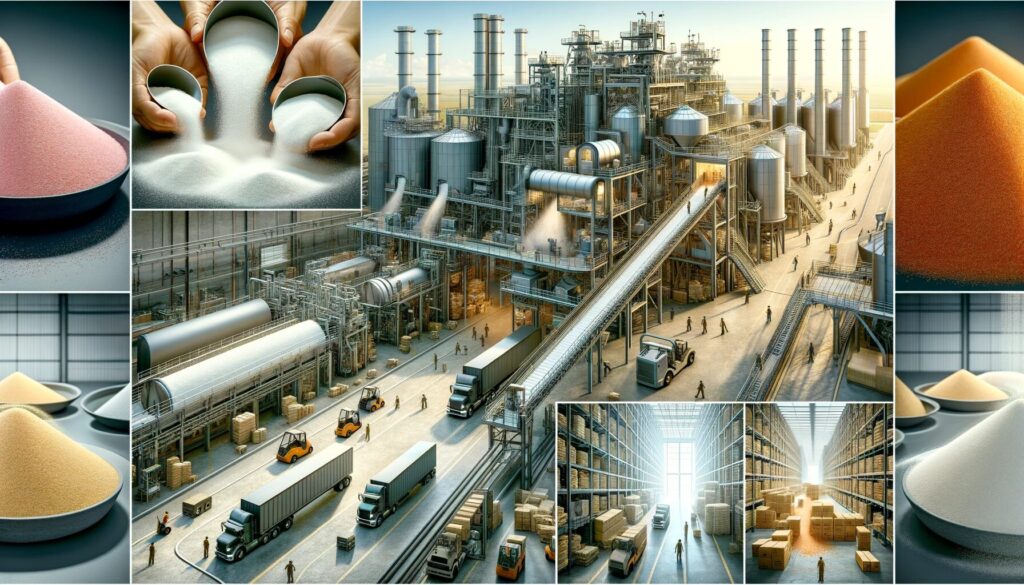

6. Refinement:

- Additional Refinement: Raw sugar can be further refined to remove impurities and improve its quality. This includes additional dissolution, filtration, and crystallization.

7. Packaging and Distribution:

- Packaging: Refined sugar is dried and packaged for distribution and sale.

- Byproducts: Molasses and bagasse are valuable byproducts. Molasses is used in rum and ethanol production, while bagasse is used as fuel or raw material for various products.

This process demonstrates how sugarcane is transformed from its natural state into the granulated sugar we know, highlighting an industry that is both technology and labor-intensive. Additionally, sugar production is an example of how an agricultural product can have multiple byproducts and applications, both in the food and energy sectors.

AgronoBlog – Agriculture Blog

AgronoBlog – Agriculture Blog