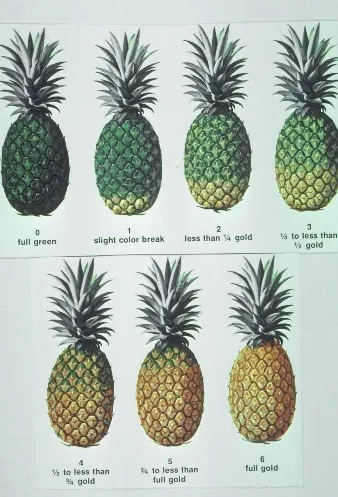

The pineapple fruit is harvested when it reaches firmness and ripeness. Pineapples do not improve their eating quality after harvest. The sugar content does not increase after harvest. Therefore, the fruit must be picked at the optimal stage of ripeness for the intended market.

Quality indices of pineapple

- Uniform size and shape

- Firmness

- No deterioration

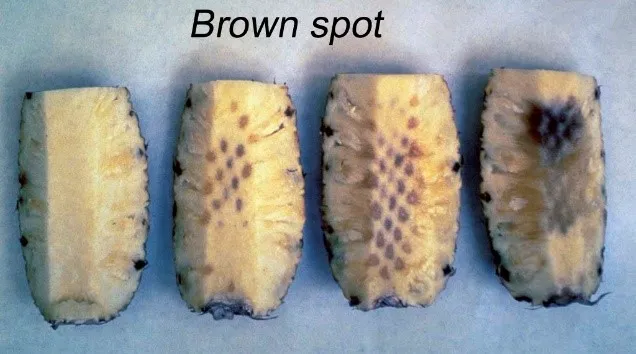

- Freedom from sunburn, scald, cracks, bruises, internal decay, endogenous brown spot, gummosis and insect damage.

- Top (crown leaves) – green color, medium length and straightness

- Soluble Solids Range – 11-18%; titratable acidity (mainly ascorbic acid) – 0.51-0.6%; and ascorbic acid – 20-65 mg/100 g fresh weight, depending on cultivar and stage of ripening.

Optimum temperature for postharvest management of pineapple

- 10-13°C (50-55°F) for partially ripe pineapples.

- 7-10°C (45-50°F) for ripe pineapples.

Chilling injury on pineapple

It is important to keep pineapples at temperatures below 7°C to avoid chilling damage. Ripe fruits are less susceptible than unripe or partially ripe ones. Symptoms include a dull green color when ripe (not ripening properly), flesh, darkening of tissue, increased susceptibility to decay, wilting, and discoloration of crown leaves.

Diseases in pineapple postharvest handling

Thielaviopsis Rot (Black Rot): Caused by Thielaviopsis paradoxa, it can start in the stem and work its way through most of the pulp, the only external symptom being a slight darkening of the skin due to the skin soaking in water on the rotten parts of the pulp. As the meat softens, the top skin breaks easily under light pressure.

Fermentation in pineapple

Caused by Saccharomyces spp, it is usually associated with overripe fruit. The yeast enters the fruit through wounds. The fruit pulp becomes soft and bright yellow and breaks open with large gas cavities.

Control

Careful handling to minimize mechanical injuries.

Rapid cooling and maintenance of optimum temperature and relative humidity during all post-harvest handling operations.

Application of fungicides, such as thiabendazole (TBZ).

Wax

Pineapple fruit must be waxed after cleaning and drying. There are several types of waxes suitable for pineapples, which can be applied by dipping or by spraying. The most used waxes for pineapples are mixtures of carnauba and paraffin or polyethylene and paraffin. The type of wax chosen must be approved by the importing country, if the market destination is export. The wax should be applied only to the surface of the fruit and not to the crown, as many waxes cause damage to the crown. The beneficial effects of wax include reduced internal browning of the fruit, less moisture loss and a brighter external appearance.

AgronoBlog – Agriculture Blog

AgronoBlog – Agriculture Blog