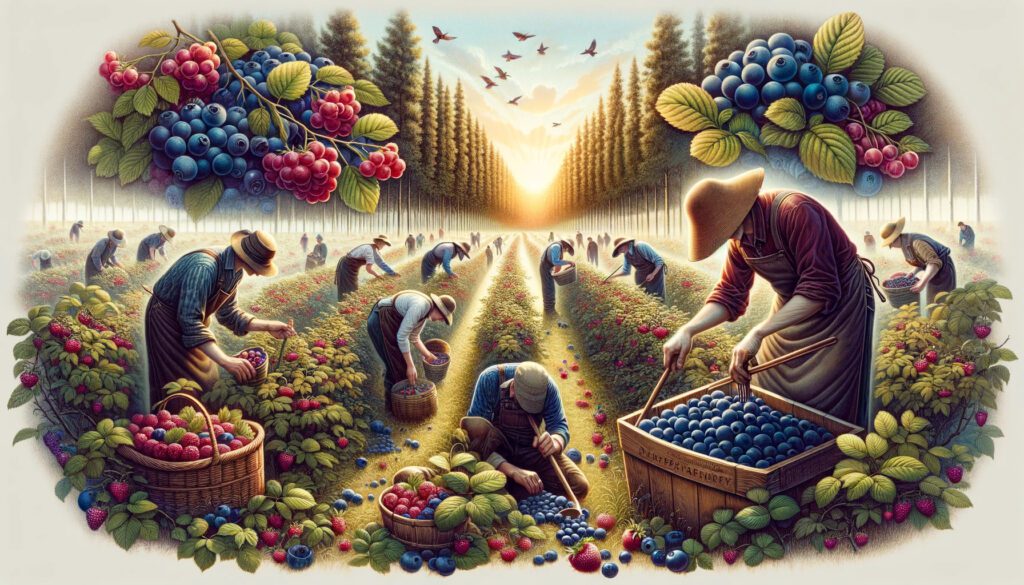

The harvest and postharvest of berries are crucial phases to ensure the quality and shelf life of these fruits. Here are some important aspects of these stages:

Optimal Berry Harvest Time

Berries should be harvested when fully ripe, as they do not continue to ripen after being picked.

The optimal harvest time for the most common types of berries varies depending on the species, climatic conditions, and cultivation environment. Identifying the right time is crucial to ensure the best quality and flavor of the fruit. Below are the optimal times for some of the most common berries:

1. Strawberries (Fragaria spp.)

- Harvest Time: When strawberries reach a bright red color all over, with no green areas around the stem.

- Indicators: They mature approximately 4-6 weeks after flowering. Firmness and full flavor are good indicators.

2. Blueberries (Vaccinium spp.)

- Harvest Time: When the fruits are completely blue, without reddish or green hues.

- Indicators: Blueberries are ready to harvest a few days after reaching their full color. They should detach easily from the bush.

3. Raspberries (Rubus idaeus)

- Harvest Time: When they acquire a deep red color (or purple/black in specific varieties) and separate easily from the receptacle.

- Indicators: They mature over several weeks, allowing multiple harvests.

4. Blackberries (Rubus spp.)

- Harvest Time: When blackberries reach an intense black color and detach easily from the stem.

- Indicators: Soft to the touch and slightly soft.

5. Currents (Ribes spp.)

- Harvest Time: When red and white currants become translucent and black ones reach a deep black color.

- Indicators: Red and black currants are usually ready for harvest in mid-summer.

General Considerations

- Maturity vs. Firmness: For some berries, like blueberries, firmness can indicate higher antioxidant content, though perhaps not the maximum flavor.

- Manual Harvest: Most berries require manual harvesting due to their delicacy.

- Harvest Frequency: Some berries, like raspberries, may require daily or every other day harvesting during the production season.

It is essential to regularly monitor crops, as the time from ripeness to over-ripeness can be brief, especially in intense heat conditions. Experience and observation are key to determining the optimal harvest time in each case.

Berry Harvesting Techniques

The harvesting techniques for berries are fundamental to guarantee the quality and viability of these delicate fruits. Given that berries are delicate and prone to damage, harvesting requires a careful approach. Here are some techniques and general considerations for harvesting the most common berries:

Manual Harvesting

Gentle Technique: Use a gentle technique to pick the fruits, avoiding squeezing or damaging them.

Selection: Choose only fruits that are fully ripe, as most berries do not ripen after being harvested.

Tools: Often harvested with bare hands or soft gloves to minimize damage.

Use of Suitable Containers

Shallow Containers: Use baskets or containers that are not too deep to avoid the weight of the top fruits crushing those below.

Avoid Overloading: Do not overfill the containers to prevent pressure damage.

Harvest Timing

Early in the Morning: Harvesting in the early hours of the morning can be ideal, as the fruits are fresher and firmer.

Dry Days: Prefer to harvest on dry days, as wet berries are more susceptible to rot and damage.

Harvest Frequency

Regularity: Some berries, like raspberries and blackberries, may require harvesting every 1-2 days during the production season.

Constant Monitoring: Regularly inspect fields to determine the need for harvesting.

Mechanized Harvesting (in some cases)

Specialized Equipment: For certain large-scale operations, like some varieties of blackberries, mechanical harvesters can be used.

Considerations: Mechanical harvesting is only suitable for berries that can withstand a certain degree of rough handling without getting damaged.

Immediate Post-Harvest

Post-Harvest Handling: Quickly move harvested berries to a cool, shaded place for sorting and packaging.

Rapid Cooling: Cool the berries as soon as possible to extend their shelf life and maintain quality.

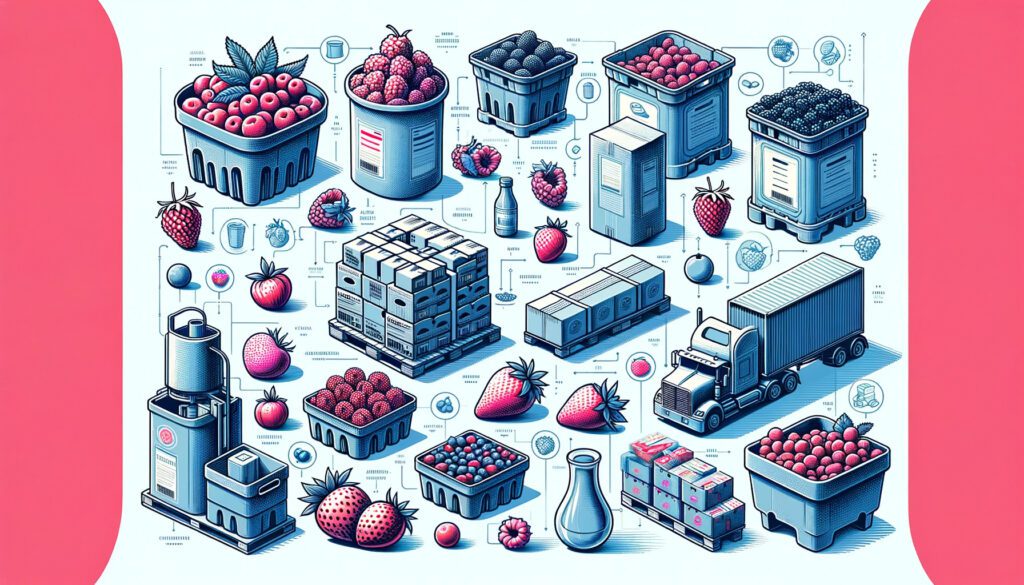

Sorting and Packaging

Careful Sorting: Remove damaged, diseased, or unripe fruits.

Packaging for Transport: Use packaging that allows proper ventilation and protects the fruits during transport.

Food Safety Considerations

Hygiene: Maintain high hygiene during harvesting to prevent contamination.

Staff Training: Ensure workers are trained in proper harvesting techniques and hygiene practices.

Berry harvesting is a laborious and delicate process. Careful handling during harvest is crucial to maintain the integrity and quality of the fruits, which in turn impacts their market value and consumer acceptance.

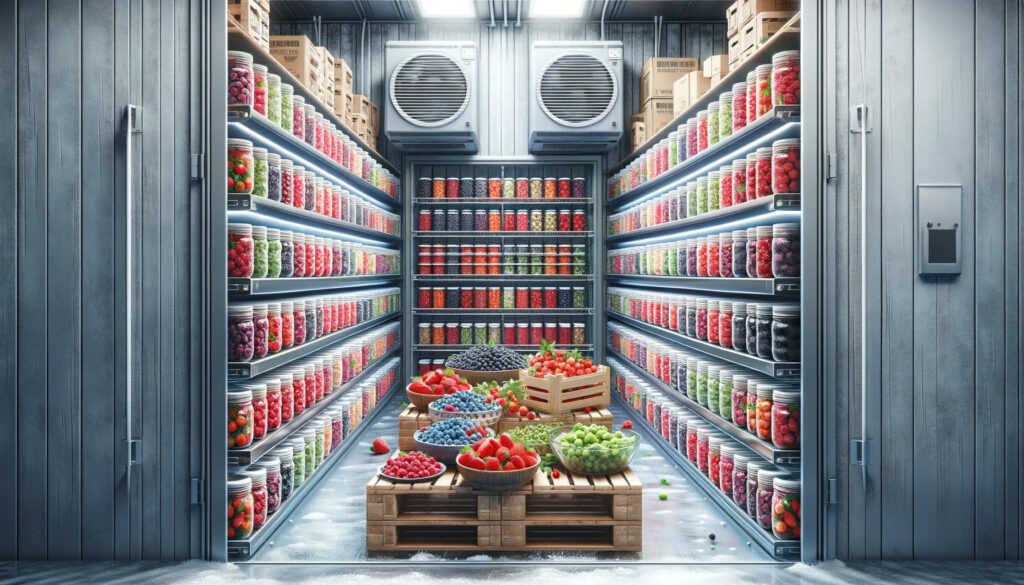

Post-Harvest of Berries

The post-harvest of berries is a critical stage to maintain their quality and prolong shelf life. Berries are highly perishable fruits, and their post-harvest handling requires special care to minimize deterioration and maintain freshness. Here are some important aspects in the post-harvest of berries:

Rapid Cooling

Importance: Rapidly reducing the temperature of berries after harvest is essential to slow down respiration and ripening.

Methods: Forced air cooling or refrigeration in cold storage rooms can be used.

Careful Handling

Gentle Manipulation: Berries are susceptible to mechanical damage. Minimize handling and do it carefully.

Transport and Packaging: Use packaging that protects the fruits during transport and allows proper ventilation.

Storage

Temperature: Store at low temperatures, generally between 0-4°C.

Relative Humidity: Maintain high relative humidity, around 90-95%, to prevent water loss and dehydration of the fruits.

Atmospheric Control: In some cases, storage in controlled or modified atmospheres is used to extend shelf life.

Quality Control

Selection and Sorting: Remove damaged, overripe, or diseased fruits. Sort berries according to size, color, and quality.

Regular Inspections: Conduct regular inspections during storage to detect and remove deteriorated fruits.

Packaging for Sale

Attractive Packaging: Use packaging that is attractive to consumers and protects the fruits.

Labeling: Include relevant information such as origin, harvest date, and storage tips.

Transportation

Controlled Conditions: Transport in refrigerated vehicles to maintain the cold chain.

Handling During Transport: Avoid exposure to high temperatures and direct sunlight.

Hygiene and Food Safety

Hygienic Practices: Maintain high standards of cleanliness in all post-harvest stages to prevent contamination.

Compliance with Regulations: Follow local and international food safety regulations.

Marketing and Sales

Quick Marketing: Due to their short shelf life, berries should be marketed quickly.

Promotion of Freshness: Emphasize the freshness and quality of the fruits to attract consumers.

Success in the post-harvest phase of berries depends on careful attention to detail at each step. Proper management can significantly improve the shelf life of berries, reduce losses, and ensure that fruits reach the consumer in the best possible condition.

AgronoBlog – Agriculture Blog

AgronoBlog – Agriculture Blog